Wheels for special purposes

Steel, forged wheels, wheels with tyres, without tyres for cranes, travelling carts, trailers, repair service trucks of quality and hardness based on requirements.

General information

Travel crane wheels are made of forged version. They are adapted to all usual types of rails and resist well to stress caused by the crane travel.

Based on their specific determination for heaviest environment these wheels are supplied in various versions and quality.

material quality according to DIN 1.7225 with hardness up to 500 HB,

material quality according to DIN 1.1231 with hardness from 600 to 700 HB,

dimensions pursuant to the standard DIN or the investor´s drawing from the diameter 250 and above 1000 mm,

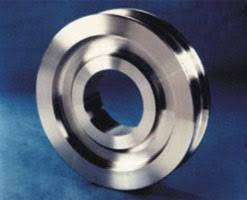

version with one or two flanges,

version with processed or non-processed hole, with wedge or without wedge groove.

We can supply also wheels without flanges at request.

At customer’s request, a qualitative certificate as well as material analyzes of chemical and mechanical properties can be issued.

Production

The semi-product is forged in closed die at pressure of 10 000 tons.

This production method ensure high quality, good material structure as well as high strength with conservation of equal structure composition even after the wear of travel surfaces.

Thermal treatment

Various hardening procedures of surfaces ensures the required hardness for travel and inside flange surface.

Various procedures of thermal treatment ensure the required metallurgic and mechanical properties of forged crane wheels.

Quality

Continuous quality tests of material with non-destructive methods using ultrasound or magneto scope methods are made in the production of crane wheels. Following the final dimensional check the wheels are equipped with identification mark and protective layer protecting them during their transport and storage.

The quality certificate as well as material analyses of chemical and mechanical properties can be issued at client´s request.

Request process:

- 1.1 Your request

- 1.2 Production as required

- 1.3 Accessories and scope of delivery

- 1.4 Quality and hardness of the material

For any demand we send our technical questionnaire. In case of specific shape

Enclose, please, a drawing.

Crane wheels are exclusively made with forging.

The delivery does not include bearings, gears etc.

The delivery includes:

semi-product of crane wheel, including processed travel surface (average B +/- 0,2 mm)

and processed inside flange surface,

hole diameter is made in semi-finished version (average A = 6 mm),

or in finished version (diameter A with tolerance H7 or H6),

side surfaces are turned (roughness 12,5u).

Standard deliveries correspond to following standards:

42 Cr Mo 4 (ČSN 15.142) or DIN 1.7225 or AISI 4142 or BS 708 M40

Yield point: 800 – 900 N/mm2.

Required hardness need to be specified, for example: 300/400HB or 450/500HB or 600/700HB,

At hardness 600/700HB the material AISI 1070, or DIN 1.1231 is used in production.

Hardening depth is in the scope 6 – 30 mm, in standard case 15 – 16 mm.

Used materials after being forged and before the special hardening have the hardness from 250 to 300 HB.

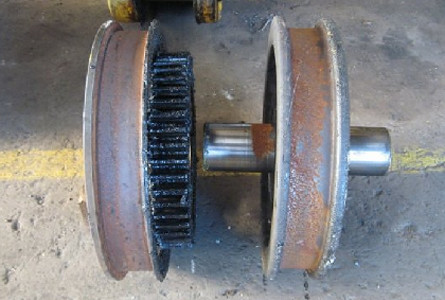

- after the diameter wear by 10 mm,

- when metal particles of size more than 1 mm are broken out from the travel surface,

- when the travel surface hardness is reduced by 30 % following its repeated processing,

- when fissures are found on the inside flange surface,

- when side flange is worn by more than 0,2 mm