Fastening systems, clamps and pads

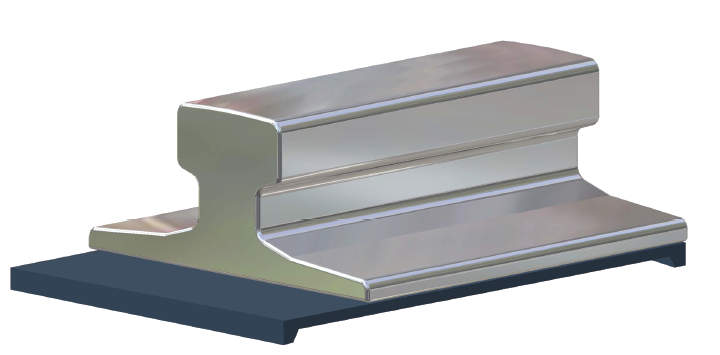

Railway and crane fixing systems, clamps and pads Gantry Rail, VE, VO, VM with or without flexible tip with rectification option.

1:1 Concrete sleepers

1:2 Wooden sleepers

1:3 Tramvays

2:1 Fully-elastic and semi-elastic laying

2:2 Fixed laying

3:1 Continuous

3:2 Discontinuous

1: Railway

Concrete sleepers, wooden and tramway sleepers

Deliveries of clamps and pads of various types for fastening of railway and tramway rails.

2: Cranes, rack chargers and other applications – fastening systems

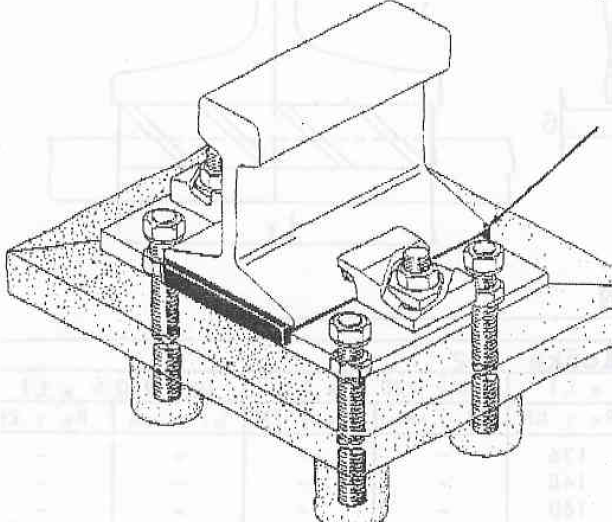

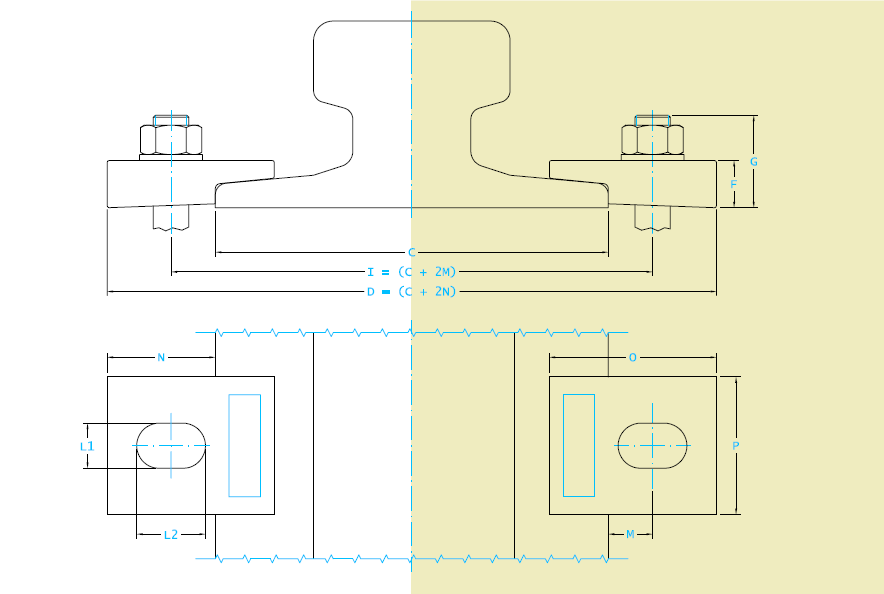

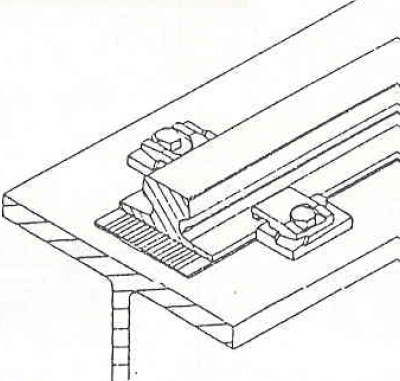

2:1 Fully-elastic and semi-elastic fastening of rails

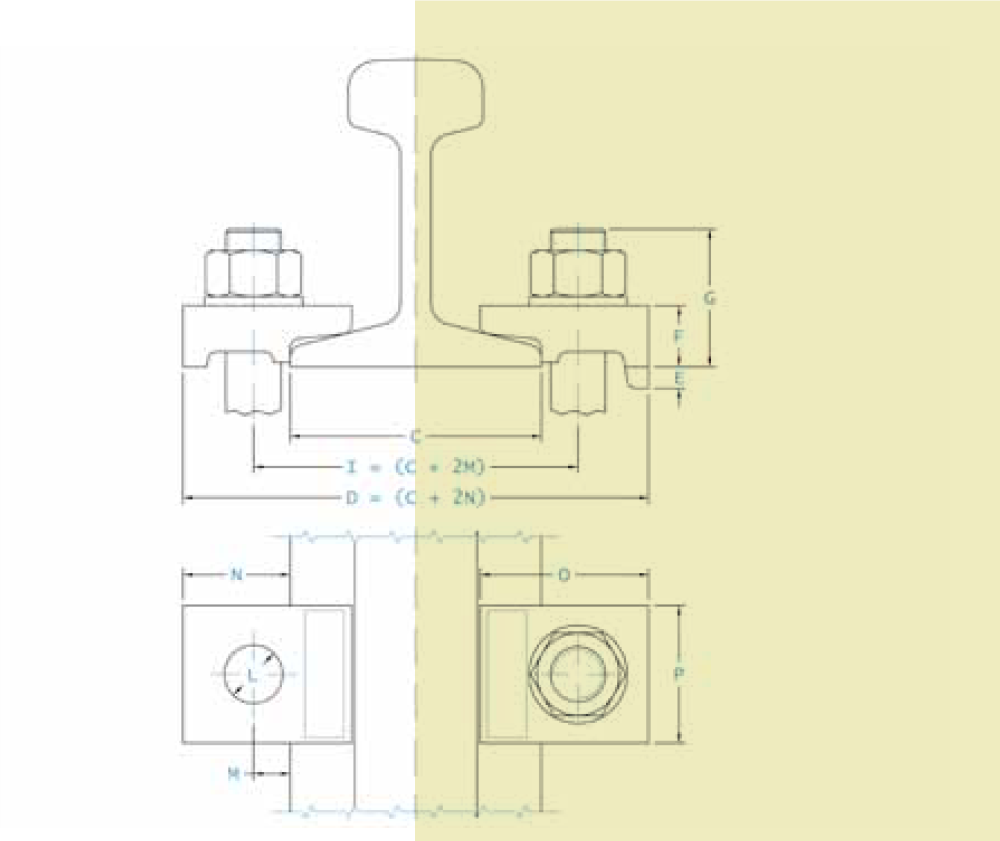

- Fully-elastic and adjustable – rectifiable fastening of rails, using the system GANTRY.

- Clamps with elastic fastening can be divided in welded and screwed clamps for fastening of rails.

- The rail can be laid, based on the type of pad, in continuous or discontinuous manner of fastening.

- Semi-elastic fastening of rails using the system Gantry, MX, VX

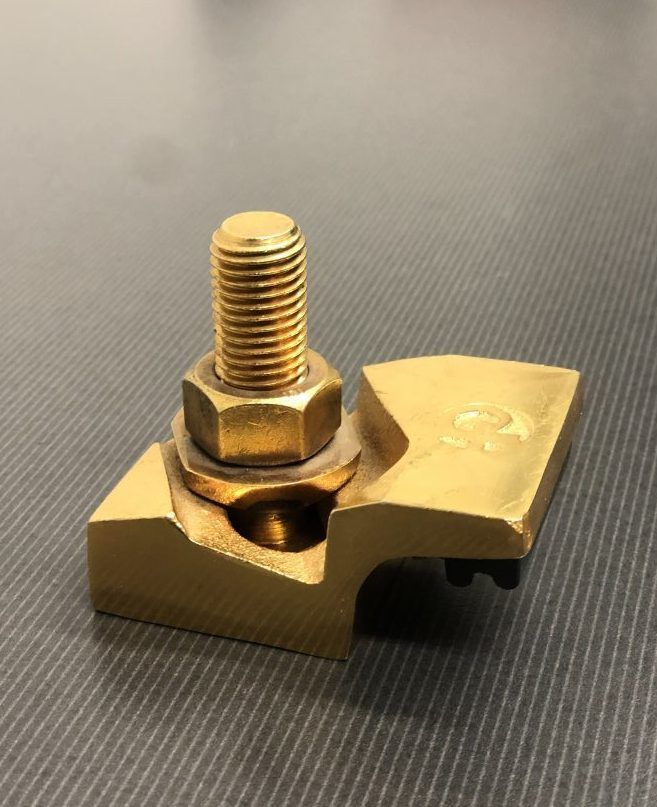

Clamps

Option to supply also the gold-plated clamps pursuant to the partner´s requirements.

| Technical properties: | |

|

|

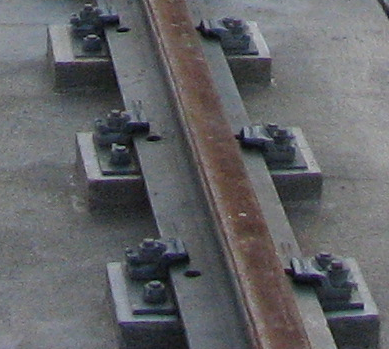

2:2 Fixed laying without rectification option – standard

Fixed laying of rails, system Gantry, VX

Technical properties:

- not centred loading “steel to steel” and thus increased wear of travel profile and travel wheels. It is due to the concentrated load of travel profile and to the risk of fissures in weld joints

- high level of noise and lower structures of crane track and the crane bridge are loaded with vibrations

- too much expensive exchange of travel profile due to the wear or the non-observance of tolerances

- possibility of incorrect laying with regard to the beam post

3: Pads

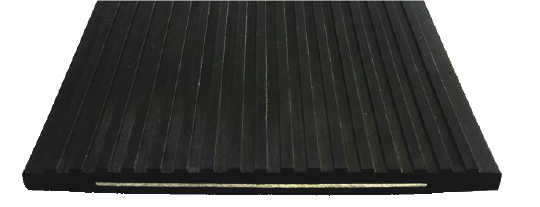

3:1 Continuous

Properties:

Shore hardness A: 75 ºC +/- 5 ºC pursuant to DIN 53505

Tensile strength: 16 N/mm² pursuant to DIN 53505

Ductility: 300 % pursuant to DIN 53505

Permanent deformation: 5 % max. A at 23 ºC

Temperature of use: – 30 ºC to 130 ºC

Noise reduction in dBA: 10 %

Vibration reduction : 40- 45 %

Max. loading : 120 Kg/ cm²

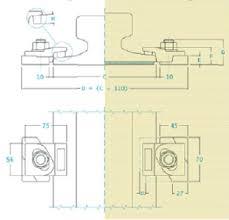

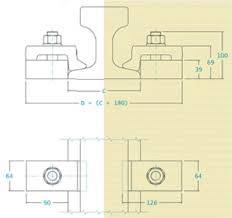

Dimensions : E- 6 mm, F- 7,5 mm, D – based on the width of rail flange

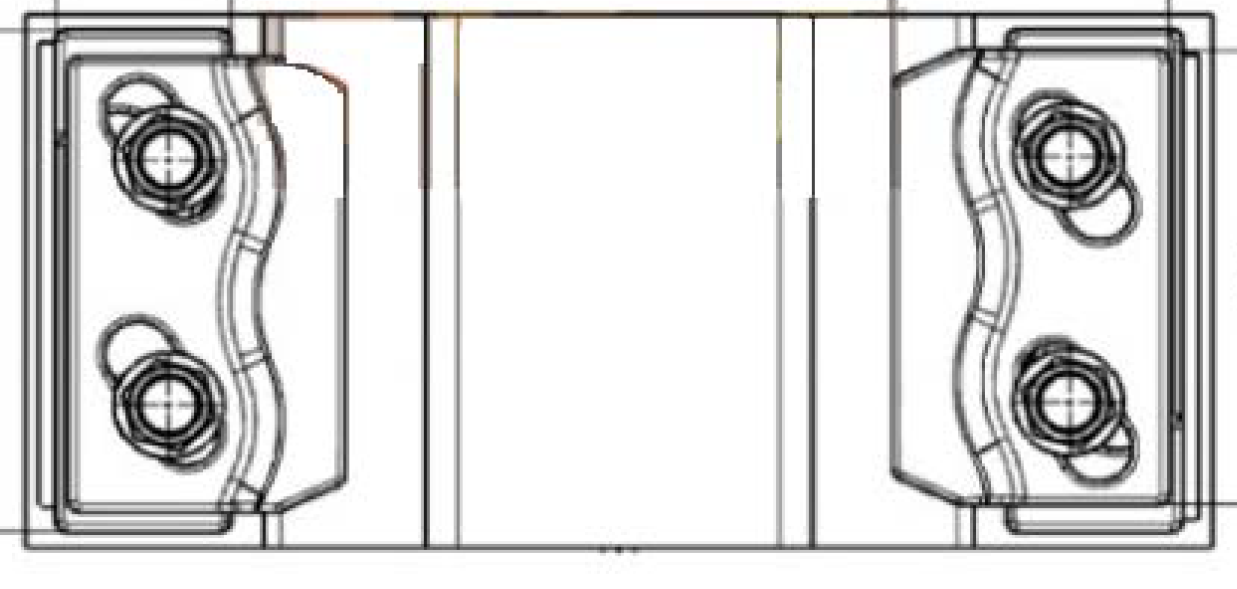

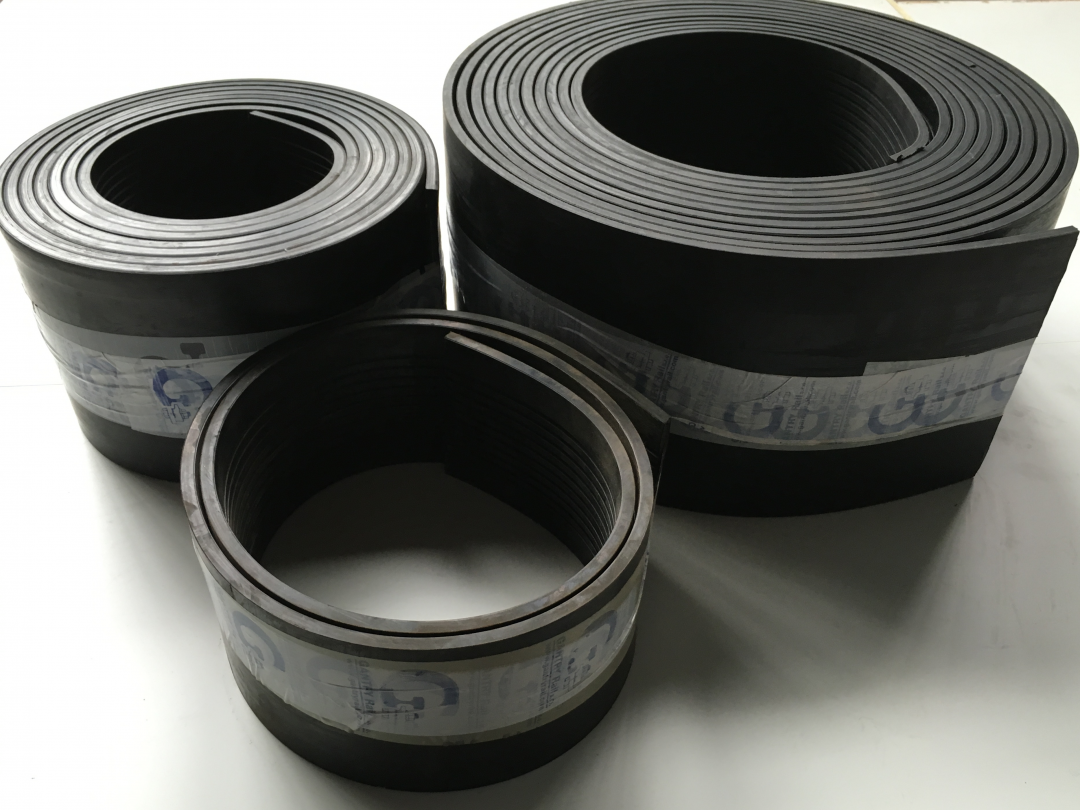

3:2 Discontinuous

For discontinuous laying of rails:

It evenly distributes the load on lower structure.

It avoids the point load and thus occurring fatigue effects.

It balances surface inequalities and thus improves the rail contact.

It reduces rail and tie-plate wear.

Properties of material: copolymer EVA – it resists greases, acids, UV light.

Temperature of use : from -25 °C until + 75 °C.